Understanding High-Quality 3D Printing Services

Definition and Importance of High-Quality 3D Printing

Imagine a world where every intricate detail, every delicate curve, and every robust structure is brought to life with astonishing precision. High-quality 3D printing services transcend mere fabrication; they are the artisans behind the seamless fusion of imagination and reality. In the realm of modern manufacturing and design, the importance of exceptional quality cannot be overstated. It’s this mastery that transforms prototypes into tangible marvels, ensuring durability, accuracy, and aesthetic brilliance.

When evaluating high-quality 3D printing services, look beyond the surface—consider the materials used, the resolution achieved, and the consistency maintained across each project. These elements are the backbone of a service that elevates visions into tangible assets. For industries across South Africa, where innovation meets tradition, the significance of high-quality 3D printing is profound. It unlocks potential, fosters creativity, and solidifies a reputation for excellence, making it an indispensable tool in today’s competitive landscape.

Key Features of Top-Tier 3D Printing Services

Exceptional 3D printing is a symphony of precision, material mastery, and technological prowess. When seeking high-quality 3D printing services, discerning clients look for more than just crisp details—they demand consistency, durability, and a flawless finish that elevates every project. The hallmark of top-tier 3D printing lies in its ability to faithfully reproduce intricate designs while maintaining structural integrity.

Key features that distinguish the best high-quality 3D printing services include advanced resolution capabilities, a wide range of premium materials, and meticulous post-processing techniques. These elements ensure that prototypes and final products aren’t just visually stunning but also resilient enough for real-world use.

- High-resolution layer accuracy

- Use of durable, industry-grade materials

- Dependable repeatability across multiple projects

In South Africa’s competitive landscape, choosing a 3D printing provider that combines these features can turn innovative concepts into tangible realities—sometimes with a touch of the extraordinary. After all, it’s in the details where true craftsmanship is revealed, and in high-quality 3D printing services, every detail matters!

Common Industries Benefiting from High-Quality 3D Printing

Across South Africa, industries are increasingly harnessing the power of high quality 3d printing services to turn visionary ideas into tangible realities. This technology’s ability to produce complex, precise, and durable components is revolutionizing sectors from healthcare to manufacturing. In particular, the medical field benefits immensely, with custom prosthetics and surgical models that improve patient outcomes and streamline procedures.

Similarly, the automotive and aerospace industries rely on high quality 3d printing services for rapid prototyping—saving time and reducing costs while ensuring parts meet rigorous standards. Architectural firms also utilize these services to craft detailed scale models that vividly bring their designs to life, captivating clients and stakeholders alike.

In the realm of creative design and jewelry, artisans leverage high-quality 3d printing services to achieve intricate details that would be impossible by hand, elevating their craft to new heights. From functional prototypes to artistic masterpieces, these services enable innovation across diverse fields, proving that when quality is prioritized, the results are truly extraordinary.

Types of 3D Printing Technologies for Superior Results

FDM / FFF (Fused Deposition Modeling)

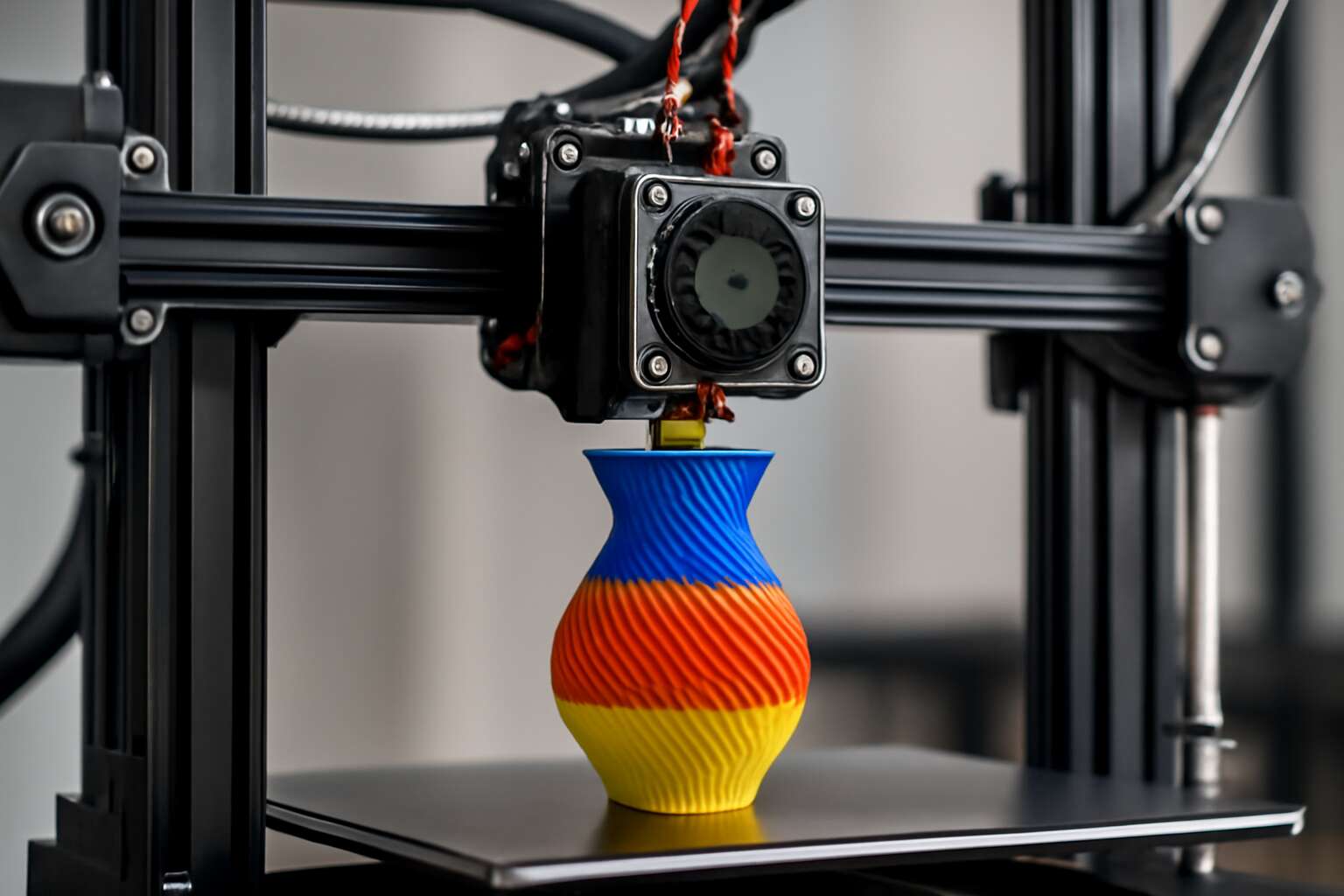

Within the realm of high quality 3d printing services, understanding the different technologies that underpin precision and durability is crucial. One of the most widely adopted methods is FDM / FFF (Fused Deposition Modeling / Fused Filament Fabrication). This technology works by extruding thermoplastic filaments, layer by layer, to create complex geometries with remarkable detail. Its popularity stems from its versatility and cost-effectiveness, making it a go-to choice for prototypes and functional parts alike.

What sets FDM / FFF apart in high quality 3d printing services is the ability to tailor material selection for specific needs—ranging from ABS and PLA to more advanced composites. For industries demanding robustness and intricate design, this technology offers a perfect blend of speed and quality. Sometimes, the difference between a good print and a masterpiece hinges on the precision of layer adhesion and temperature control.

For those seeking superior results, selecting a provider with mastery over FDM / FFF technology ensures every project benefits from meticulous calibration and expert material handling. Whether it’s rapid prototyping or producing end-use parts, this technology remains an essential pillar of high quality 3d printing services, elevating the craft from merely functional to truly exceptional.

SLA (Stereolithography) and Resin Printing

SLA (Stereolithography) and resin printing have revolutionized the landscape of high quality 3d printing services. Unlike filament-based methods, resin printing harnesses liquid photopolymers that cure with precision under UV light, resulting in astonishingly detailed and smooth surfaces. This technology is perfect for projects requiring intricate features and fine resolution, making it a favorite among designers and engineers alike.

What truly sets SLA apart is its ability to produce complex geometries with razor-sharp accuracy—often down to the micrometer. For industries such as jewelry, dental, or miniature modeling, this level of detail can be the difference between an ordinary prototype and a masterpiece. The process’s speed and accuracy make it an indispensable tool for those demanding nothing but the best in high quality 3d printing services.

Here’s a quick glance at why resin printing is a game-changer:

- Unmatched surface finish with minimal post-processing

- High resolution capable of capturing tiny details

- Wide variety of resins for different applications, from flexible to rigid

When paired with expert calibration and the right resin selection, resin printing elevates high quality 3d printing services into an art form. It’s not just about creating parts; it’s about crafting enduring impressions that push the boundaries of what’s possible in digital fabrication.

SLS (Selective Laser Sintering)

When it comes to elevating the standards of digital fabrication, SLS (Selective Laser Sintering) stands as a true marvel in the realm of high quality 3d printing services. Unlike traditional methods, SLS employs a powerful laser to fuse powdered materials—such as nylon, glass-filled composites, or even metals—layer by layer, forging durable and intricate parts. The result? Complex geometries with a level of precision that borders on the extraordinary, making it ideal for industries demanding both strength and finesse.

What makes SLS particularly compelling is its versatility and ability to produce parts with minimal post-processing. This technology excels in creating prototypes, functional components, or even small-batch production runs, all with impeccable surface finish and dimensional accuracy. For those seeking high quality 3d printing services, SLS offers a seamless blend of durability and detail that transforms visionary concepts into tangible realities.

- Precision engineering for complex designs

- Use of durable, high-performance materials

- Fast turnaround times for prototypes and production

In the ever-evolving landscape of digital manufacturing, SLS continues to push boundaries, enabling industries from aerospace to medical devices to harness its full potential. It’s a cornerstone technology for high quality 3d printing services that demand nothing but the best, turning imaginative ideas into enduring masterpieces.

DLP (Digital Light Processing)

Among the diverse landscape of 3D printing technologies, Digital Light Processing (DLP) stands out as a marvel of precision and speed, especially when seeking high quality 3D printing services. Unlike traditional methods, DLP uses a digital projector to cure liquid resin layer by layer, creating highly detailed and smooth surfaces. This process allows for intricate designs that demand fine resolution and exceptional surface finish, making it perfect for applications where detail truly matters.

One of the most compelling aspects of DLP technology is its rapid production capability. It can produce complex prototypes or small batch runs in a fraction of the time compared to other methods. Moreover, the use of specialized resins results in durable, high-performance parts that can mimic the look and feel of finished products. For industries such as jewelry, dental, or even miniature models, DLP offers a level of craftsmanship that elevates any project to new heights.

- Unmatched detail resolution

- Fast turnaround for prototypes

- Wide selection of high-performance resins

In essence, DLP technology embodies the promise of high quality 3d printing services—delivering precision, speed, and finesse that transform visionary ideas into tangible, flawless pieces. It’s a cornerstone for those who refuse to settle for anything less than the best in digital fabrication.

Choosing the Right Technology for Your Project

Choosing the right 3D printing technology for your project is not merely a matter of preference; it is a profound decision that influences the very essence of your creation. Each method, from FDM to SLS, SLA, and DLP, offers a unique lens through which your ideas are translated into reality. While FDM might serve well for functional prototypes, it often lacks the finesse required for intricate designs that demand high resolution.

SLA and DLP, in particular, stand out when seeking high quality 3D printing services. These technologies excel in delivering exceptionally smooth surfaces and fine detail, crucial for industries like dental or jewelry manufacturing. For projects where precision and surface finish are paramount, DLP’s rapid layer curing and vast resin selection make it an unrivaled choice.

- Complex geometries and fine detail

- Rapid production cycles

- High-performance, durable resins

Ultimately, the choice hinges on understanding the nuanced demands of your project and aligning them with the capabilities of each technology. High quality 3D printing services are more than just a technical offering—they are a gateway to materializing visions with unmatched clarity and finesse.

Materials for Premium 3D Prints

Plastic Filaments and Resins

When it comes to high quality 3D printing services, the choice of materials can transform an ordinary prototype into a masterpiece of precision and durability. Premium plastic filaments and resins are the backbone of intricate designs, offering a perfect balance between strength, flexibility, and fine detail. In South Africa, the demand for these refined materials has surged as industries recognize the potential of 3D printing to innovate and streamline production processes.

For projects demanding exceptional clarity and surface finish, photopolymer resins stand out. These resins cure under specific light wavelengths, resulting in stunningly detailed models with smooth surfaces. Conversely, plastic filaments such as ABS, PLA, and PETG are favored for their versatility and robustness in FDM/FFF printing. They serve a wide spectrum of applications, from functional prototypes to artistic sculptures.

Choosing the right material is crucial, and many top-tier 3D printing services offer an array of options to meet unique needs. Whether you require the flexibility of TPU or the heat resistance of nylon, selecting the appropriate plastic filament or resin elevates the final product’s quality and performance. The right material, paired with advanced 3D printing technology, unlocks endless creative possibilities!

Metals and Alloys

Metals and alloys are transforming the landscape of high quality 3D printing services in South Africa. When strength, heat resistance, and precision are non-negotiable, metal 3D printing provides unmatched capabilities. From aerospace components to medical implants, metals like titanium, stainless steel, and aluminum are increasingly used to produce durable, complex parts. These materials enable the creation of intricate geometries that traditional manufacturing cannot match.

Advanced metal 3D printing techniques such as direct metal laser sintering (DMLS) and selective laser melting (SLM) have made it possible to work with a wide range of alloys. They offer excellent mechanical properties and surface finishes. For industries demanding high performance, choosing the right metal or alloy is crucial. Whether it’s the corrosion resistance of Inconel or the lightweight nature of aluminum alloys, the right material enhances both functionality and longevity.

Many high quality 3D printing services in South Africa now incorporate a variety of metal options, including:

- Titanium alloys for aerospace and medical applications

- Stainless steel for industrial prototypes

- Aluminum for lightweight structural parts

By leveraging these premium metals and alloys, 3D printing providers deliver products that meet rigorous standards of durability and precision, opening new avenues for innovation and craftsmanship. Metal 3D printing is no longer just a niche; it’s a game-changer for high quality 3d printing services across industries in South Africa and beyond.

Composite Materials

In the realm of high quality 3d printing services, composite materials emerge as a transformative force. They unlock possibilities that traditional manufacturing can only dream of, offering a blend of strength, flexibility, and lightweight characteristics. These materials are crafted to push the boundaries of what 3D printing can achieve, allowing for the creation of complex geometries with unparalleled precision.

Composite materials such as carbon fiber-reinforced plastics and reinforced polymers are becoming increasingly popular among South African industries seeking durability and high performance. Their unique properties enable the production of parts that are both robust and lightweight—a crucial advantage in fields like aerospace, automotive, and high-performance sports equipment.

High quality 3d printing services leverage these advanced composites to deliver products with exceptional structural integrity. Whether it’s for prototypes or end-use components, the integration of composite materials ensures that each piece embodies both resilience and design excellence. As the demand for innovative manufacturing solutions grows, composite materials stand at the forefront of this evolution, fueling a new era of craftsmanship and engineering ingenuity.

Specialty and Innovative Materials

When pushing the boundaries of innovation, selecting the right materials is crucial for achieving true excellence in 3D printing. Specialty and innovative materials elevate high quality 3D printing services from mere prototyping to producing parts with exceptional durability, heat resistance, and aesthetic appeal. These advanced substances open doors to applications once thought impossible, making them a game-changer for South African industries.

From flexible thermoplastics to ultra-strong composites, the range of materials available today is staggering. For instance, materials like metal-infused filaments and bio-compatible resins cater to specific needs with unmatched precision. Incorporating these materials ensures that each print not only meets but exceeds industry standards for resilience and performance. Whether for intricate prototypes or end-use components, high quality 3d printing services harness these specialty materials to deliver products that are both innovative and reliable.

In particular, composite materials—such as carbon fiber-reinforced plastics—are revolutionizing manufacturing. They offer an unbeatable combination of lightweight structure and high strength, making them ideal for aerospace, automotive, and sporting goods. As the demand for truly bespoke solutions grows, these innovative materials are paving the way for a new era of craftsmanship rooted in advanced technology and relentless quality.

Factors to Consider When Selecting Materials

When selecting materials for high quality 3d printing services, understanding the unique demands of your project is paramount. Not all filaments or resins are created equal, and choosing the wrong one can turn your innovative idea into a brittle failure faster than you can say “layer separation.”

Factors such as strength, flexibility, heat resistance, and aesthetic finish must be carefully weighed. For instance, if you’re producing prototypes that need to withstand mechanical stress, materials like reinforced composites or metal-infused filaments might be the way to go. Conversely, for visual models requiring fine detail, high-resolution resins excel in bringing intricate designs to life.

In the realm of high-quality 3d printing services, it’s wise to consider the specific properties of each material.

- Durability

- Temperature tolerance

- Biocompatibility

These elements influence not just the quality but the overall success of your project, whether for industrial applications or bespoke artistry. Remember, the right material choice can turn a good print into an exceptional masterpiece—something every South African innovator should aim for in today’s competitive landscape.

Factors That Define Quality in 3D Printing Services

Layer Resolution and Surface Finish

When it comes to high quality 3D printing services, two critical factors often determine the final outcome: layer resolution and surface finish. These elements are not just technical jargon; they are the very essence of what transforms a digital design into a tangible masterpiece. Precision in layer resolution ensures that every tiny detail is captured flawlessly, revealing intricate textures and delicate features that lesser services might miss. A finer layer resolution, such as 50 microns, can make the difference between a prototype that looks handcrafted and one that exudes professional finesse.

Equally important is the surface finish, which can vary from smooth and glossy to textured and matte, depending on the application. High quality 3d printing services leverage advanced post-processing techniques to elevate surface quality, reducing visible layer lines and imperfections. This meticulous attention to detail not only enhances aesthetic appeal but also improves functional performance. For industries demanding high precision and durability, such as aerospace or medical devices, these factors become non-negotiable, making the choice of a trusted provider essential.

- Layer resolution

- Surface finish

- Material compatibility

- Post-processing techniques

These elements work in harmony, ensuring each project embodies excellence—an attribute that sets top-tier 3D printing services apart in a competitive market. When you demand nothing but the best, understanding these subtle yet vital factors becomes your secret weapon for success.

Dimensional Accuracy and Tolerance

In the realm of high quality 3D printing services, precision isn’t just a feature—it’s the very foundation upon which excellence is built. One of the most pivotal factors that define the integrity of a printed masterpiece is dimensional accuracy. When a component’s measurements align flawlessly with design specifications, it ensures seamless integration, whether in aerospace, medical, or intricate engineering applications. Tolerance levels further elevate this precision, setting acceptable limits for deviations that can influence functionality. Achieving tight tolerances—often within microns—demands advanced machinery and expert calibration, hallmarks of top-tier 3D printing providers.

For discerning clients seeking perfection, understanding the importance of these elements can transform a simple project into a work of art. High quality 3D printing services excel in delivering components with impeccable dimensional accuracy, ensuring every detail is preserved and every tolerance is maintained. This meticulous standard is what separates ordinary prints from those that resonate with craftsmanship and durability, especially in industries where failure isn’t an option! It’s the subtle dance between precision and performance that truly defines the pinnacle of 3D printing excellence.

Strength and Durability

In the vast realm of high quality 3D printing services, strength and durability are the enchanted armor that elevates a printed masterpiece from mere concept to enduring artifact. These qualities are not incidental but meticulously crafted through a harmonious blend of advanced materials, precise engineering, and expert calibration. When a component withstands the relentless forces of time, wear, and environmental stress, it transforms into a testament of craftsmanship and resilience.

Particularly in industries like aerospace, medical, and industrial manufacturing, the integrity of a 3D printed part can be the difference between success and failure. To achieve such robustness, top-tier 3D printing services often employ reinforced materials, such as high-grade metals, composites, and specialty resins. These materials are selected not only for their strength but also for their ability to maintain dimensional stability under demanding conditions.

- Material quality and compatibility

- Layer adhesion and bonding techniques

- Post-processing treatments like annealing or surface hardening

By mastering these factors, high quality 3D printing services produce components that are not only precise but also built to last. The result? Printed objects that stand as enduring symbols of innovation, capable of enduring the rigors of real-world application with unwavering strength and durability. In the enchanted world of 3D printing, where every detail matters, these elements form the backbone of excellence—ensuring that each creation is as resilient as it is beautiful.

Detail and Finish Quality

In the realm of high quality 3D printing services, the finesse of detail and surface finish can transform a functional prototype into a true work of art. Precision manufacturing hinges not only on the choice of materials but also on how seamlessly layers are bonded and how meticulously the surface is refined. A flawlessly finished piece reveals the mastery behind the process—smooth surfaces, sharp edges, and consistent textures that speak to the printer’s capability and the skill of the technician.

Surface quality often determines the usability and aesthetic appeal of a printed object. Even minor imperfections can compromise the integrity of a component, especially in sectors like aerospace and medical manufacturing, where tolerances are razor-thin. That’s why high quality 3D printing services invest in advanced post-processing techniques, such as surface polishing, annealing, or coating, to elevate the final product’s finish. These finishing touches ensure the component not only looks exceptional but also performs reliably under demanding conditions.

Factors like layer resolution and the precision of bonding techniques influence the overall detail and finish. For example, high-resolution settings in resin or SLA printing can achieve intricate details that are impossible with standard methods. Moreover, the use of specialized surface treatments enhances durability and aesthetic appeal, ensuring each creation is a testament to meticulous craftsmanship. As a result, the end product embodies both visual perfection and structural integrity—hallmarks of truly high quality 3D printing services.

Post-Processing and Finishing Techniques

When it comes to high quality 3D printing services, post-processing and finishing techniques are the unsung heroes that can make or break a project. These steps, often overlooked, are crucial for achieving the smooth, precise surfaces that distinguish top-tier prints from the rest. A well-executed finish not only enhances aesthetic appeal but also ensures the part’s functional integrity, especially in demanding sectors like aerospace or medical manufacturing.

Advanced surface treatments such as polishing, coating, or annealing are employed to remove layer lines, improve durability, and create a flawless appearance. For intricate designs, high resolution in resin or SLA printing allows for extreme detail, but without proper finishing, those details can be lost. Manufacturers often rely on high quality 3D printing services that utilize specialized post-processing to elevate each object to a new standard of excellence.

In some cases, a simple surface treatment can turn a basic prototype into a piece that’s visually stunning and highly functional. The key is understanding that post-processing isn’t just about aesthetics but also about enhancing the overall performance. Whether it’s through surface smoothing or protective coatings, these techniques exemplify the meticulous craftsmanship behind high quality 3D printing services.

Benefits of Choosing High-Quality 3D Printing Services

Enhanced Prototype Accuracy

When precision is paramount, the allure of enhanced prototype accuracy becomes undeniable. High quality 3D printing services possess the almost mystical ability to transform digital visions into tangible marvels with astonishing exactness. Every tiny detail, from intricate engravings to delicate lattice structures, emerges with clarity and finesse that lesser methods could only dream of. This level of precision is not just a matter of aesthetics but a cornerstone for industries where tolerances are tight and failure is not an option.

Choosing high quality 3D printing services unlocks a realm where the boundaries of design and functionality blur. The secret lies in the advanced technology and meticulous calibration that these services employ, ensuring each prototype or component adheres to exact specifications. For sectors such as aerospace, automotive, or medical device manufacturing, this means fewer iterations, faster turnaround times, and a product that truly mirrors the original concept—every detail, every nuance preserved with unwavering fidelity.

- Minimized post-processing corrections

- Superior surface finish and intricate detail

- Consistent dimensional accuracy across multiple builds

In essence, high quality 3D printing services don’t merely produce parts—they craft precision-engineered works of art, elevating the entire manufacturing journey into a realm of excellence and reliability. This is the magic that transforms dreams into reality, with accuracy at the very heart of innovation.

Improved Product Functionality

Choosing high quality 3D printing services can significantly improve product functionality. When precision and detail are paramount, these services ensure that every component performs exactly as intended, reducing the need for costly modifications later. The superior surface finish and intricate detail achieved through advanced manufacturing techniques translate into parts that fit better and function more reliably.

Moreover, consistent dimensional accuracy across multiple builds guarantees that your production line remains streamlined and efficient. This consistency is especially critical in sectors like aerospace and medical device manufacturing, where tolerances are strict and failure is not an option. By leveraging high quality 3D printing services, companies can accelerate their development cycles, minimize waste, and enhance overall product performance—turning innovative ideas into tangible, dependable solutions.

Faster Turnaround Times

In the fast-paced world of product development, time is often as valuable as the innovation itself. High quality 3D printing services offer a decisive advantage by enabling faster turnaround times that keep your projects moving forward without sacrificing precision. Advanced manufacturing techniques streamline the entire process, reducing lead times from concept to prototype and ultimately to production. This acceleration not only shortens development cycles but also allows for real-time modifications, fostering a more agile approach to product design.

Furthermore, partnering with providers of high quality 3D printing services ensures consistency across multiple builds. This reliability means fewer delays caused by part failures or discrepancies, which can be costly and time-consuming. For industries such as aerospace or medical device manufacturing, where strict tolerances are non-negotiable, this dependable speed and accuracy are invaluable. Ultimately, leveraging high quality 3D printing services transforms ambitious ideas into tangible realities swiftly, empowering businesses to stay competitive and innovative in a demanding market.

Cost-Effective Production in the Long Run

Opting for high quality 3D printing services doesn’t just mean better prototypes; it’s a savvy investment that pays off in the long run. When precision and durability are non-negotiable, cutting corners with cheaper alternatives can lead to costly setbacks. High-quality 3D printing ensures your parts are consistently accurate, reducing waste and rework—two enemies of cost-effectiveness. It’s like having a crystal ball that predicts your manufacturing future, giving you reliable results every time.

In addition, the durability of your printed components directly influences their lifespan and functionality, translating into fewer replacements and repairs. This durability, coupled with superior surface finishes, minimizes the need for extensive post-processing—saving both time and money. For businesses eyeing scalable production, partnering with providers of high quality 3D printing services ensures that every iteration aligns perfectly with your specifications, making your investment truly worthwhile.

Ultimately, high quality 3D printing services turn complex ideas into tangible, cost-efficient realities—an essential ingredient for staying competitive in South Africa’s vibrant manufacturing landscape. Whether you’re prototyping or producing end-use parts, choosing top-tier 3D printing guarantees a smarter, more economical path forward.

Customizability and Complex Designs

When it comes to bringing complex ideas to life, the flexibility of high quality 3D printing services truly shines. One of the standout benefits is the ability to realize intricate, highly customized designs that traditional manufacturing methods often struggle to produce efficiently. From detailed prototypes to bespoke end-use parts, high-quality 3D printing services can accommodate a wide array of complex geometries without sacrificing precision or surface finish.

Moreover, this level of customization can significantly streamline production processes. For instance, businesses can rapidly iterate prototypes with varying features, enabling faster design validation. This adaptability makes high quality 3D printing services indispensable for industries that demand precision and uniqueness—think aerospace, healthcare, or even bespoke manufacturing in South Africa. With advanced technology, such as SLA or SLS, intricate internal channels, delicate lattice structures, or organic shapes are no longer a challenge but a standard feature.

In essence, choosing high quality 3D printing services unlocks a realm of possibilities—empowering organizations to push boundaries and innovate boldly. The ability to produce highly customized, complex designs offers a competitive edge that simply cannot be matched by conventional manufacturing methods, especially when precision and detailed craftsmanship are non-negotiable.

How to Find Reputable High-Quality 3D Printing Providers

Assessing Service Portfolios and Capabilities

In the fast-evolving realm of manufacturing and prototyping, finding reputable high quality 3D printing services can feel like searching for a needle in a haystack. With so many providers claiming excellence, how do you separate the truly capable from the pretenders? The key lies in a meticulous assessment of their service portfolios and capabilities. A top-tier 3D printing provider will showcase a diverse array of projects—ranging from intricate prototypes to complex functional parts—demonstrating versatility and technical mastery.

Look for providers whose portfolios highlight experience across multiple industries and materials. This breadth indicates a mastery of various technologies and an ability to tailor solutions to specific needs. Assess their ability to handle different 3D printing technologies such as SLA, SLS, or DLP, which directly impacts the quality and precision of your final product. In essence, a reputable provider’s capability to adapt and innovate is often reflected in their comprehensive service portfolio, making them a reliable partner in your project’s success.

Reviewing Customer Testimonials and Case Studies

When evaluating high quality 3D printing services, delving into customer testimonials and detailed case studies can unveil invaluable insights. Genuine client feedback often highlights the provider’s consistency, reliability, and ability to meet tight deadlines—crucial elements in fast-paced industries. By examining these narratives, you gain a clearer picture of how the service provider handles complex projects and whether their quality standards align with your expectations.

Case studies, on the other hand, serve as tangible proof of capabilities. They demonstrate how the provider has navigated unique challenges, adapted to different materials, and delivered precision results. Look for examples that mirror your project’s scope—whether that’s intricate prototypes or functional end-use parts—and assess the outcomes. A reputable 3D printing provider’s portfolio should be rich with diverse success stories, reflecting their versatility and mastery in high quality 3D printing services.

- Review detailed customer testimonials for insights into consistency and customer satisfaction.

- Analyze case studies to understand the provider’s problem-solving approach and technological expertise.

- Identify examples that are similar to your project to gauge whether their capabilities match your needs.

In the pursuit of exceptional results, these reviews become your compass—guiding you toward a partner whose high quality 3D printing services are proven, reliable, and tailored to meet your specific demands. Remember, a good provider’s reputation is often built on transparency and demonstrated excellence—qualities that shine through in authentic client stories and real-world applications.

Certifications and Industry Standards

Securing high quality 3D printing services begins with verifying the credentials that underpin their capabilities. Certifications and adherence to industry standards serve as the bedrock of reliability and excellence. When evaluating potential providers, look for certifications such as ISO 9001, which signifies a commitment to quality management systems, or ASTM international standards that ensure precision and safety. These benchmarks are more than mere labels; they are indicators of a provider’s dedication to maintaining consistent, high-level output.

In South Africa, the landscape of 3D printing is rapidly evolving, making it crucial to scrutinize a provider’s compliance with both global and local standards. A reputable high quality 3D printing services provider often displays their certifications prominently, providing transparency and fostering trust. Additionally, industry-specific accreditations—especially those related to aerospace, medical, or automotive sectors—can reveal a provider’s capacity to meet rigorous regulatory demands.

- Review the provider’s documented adherence to recognized standards.

- Check for recent certifications and ongoing compliance efforts.

- Verify that the industry standards align with your project’s specific needs.

By critically assessing these elements, you can unearth a partner whose technological integrity and commitment to excellence are verified, ensuring your investment in high quality 3d printing services yields precise, durable, and reliable results. Certifications and industry standards are not just formalities; they are the silent guardians of quality in an often unpredictable digital manufacturing realm.

Turnaround Time and Cost Estimates

In the quest for top-tier high quality 3D printing services, understanding turnaround time and cost estimates can feel akin to navigating a labyrinth without a Minotaur in sight. Yet, these factors are the compass guiding your decision-making process—crucial in South Africa’s burgeoning digital manufacturing landscape. When evaluating potential providers, transparency around delivery timelines and pricing structures isn’t just courteous; it’s essential.

Reputable high quality 3D printing services providers often present detailed quotations that account for material costs, complexity, and post-processing requirements. To gain clarity, consider asking for a breakdown of each element of the quote. Some providers offer rapid prototyping with swift turnaround times, which can be a game-changer for tight project schedules. Conversely, if budget constraints loom large, requesting a cost estimate based on different material options or printing technologies can reveal significant savings without sacrificing quality.

- Assess whether the provider’s estimated timelines align with your project milestones.

- Compare initial quotes from multiple providers to identify the most cost-effective option.

- Inquire about potential delays and how they handle unforeseen issues—because, after all, even the most polished 3D printing services are not immune to hiccups.

Ultimately, the secret to securing high quality 3D printing services lies in balancing speed and cost with a discerning eye for detail—because in this domain, precision isn’t just a feature; it’s the very fabric of excellence.

Customer Support and Consultation Services

In a landscape where innovation often hinges on collaboration, finding reputable high quality 3D printing services is a pursuit rooted in trust and understanding. Customer support and consultation services are the compass that guides your journey, transforming technical jargon into clarity and confidence. When evaluating potential providers, observe how they listen—do they genuinely grasp the intricacies of your project? A provider that offers personalized consultations demonstrates a commitment to excellence, ensuring that your vision is translated with precision and care.

Effective communication isn’t merely about answering questions; it’s about fostering a partnership. Reputable providers often have dedicated support teams ready to discuss material choices, technology options, and project timelines. This dialogue can reveal a provider’s depth of expertise and their willingness to adapt to your specific needs, which is critical in South Africa’s dynamic digital manufacturing industry.

To further gauge their capability, consider asking for detailed case studies or client testimonials. These insights reveal how high quality 3D printing services have solved real-world problems, showcasing their proficiency and reliability. Remember, in this domain, the human element—empathy, transparency, and proactive guidance—can be the difference between a good service and a truly exceptional one.

Emerging Trends and Future of High-Quality 3D Printing Services

Advancements in Materials and Technologies

As the realm of high quality 3D printing services continues to evolve, the future is brimming with astonishing innovations that promise to redefine manufacturing and design. Emerging trends reveal a rapid advancement in materials and technologies, enabling creators to push boundaries previously thought unattainable. With the advent of new composite materials and enhanced printing techniques, intricate geometries and complex structures are now achievable at unprecedented levels of precision and durability.

One of the most exciting developments is the integration of advanced materials such as metal alloys and specialty resins, which open up a universe of possibilities for industries like aerospace, automotive, and healthcare. These materials not only elevate the strength and surface finish of printed objects but also expand the scope for customization and functional prototyping. As these innovations become more accessible, high quality 3D printing services are poised to become even more indispensable for turning visionary ideas into tangible realities.

- Introduction of multi-material printing for more versatile prototypes

- Enhanced layer resolution for finer detail and smoother surface finishes

- Faster printing speeds to meet increasing demand for rapid turnaround

Advancements in technologies such as digital light processing (DLP) and selective laser sintering (SLS) continue to propel the industry forward, making it possible to achieve higher accuracy and intricate detailing. The convergence of these innovations hints at a future where high quality 3D printing services will not only serve traditional manufacturing needs but also unlock creative potential in ways we are only beginning to imagine. The journey ahead is truly a marvel of engineering and artistry, promising a new era of possibility for industries and individual creators alike.

Integration with AI and Automation

The future of high quality 3D printing services is already being shaped by groundbreaking integration with AI and automation. These advancements are transforming how prototypes and products are designed, manufactured, and delivered. Artificial intelligence enables smarter print planning, minimizing errors and optimizing material usage for cost efficiency. Automation streamlines workflows, allowing for faster turnaround times without sacrificing precision.

Emerging trends include the deployment of machine learning algorithms that enhance layer resolution and surface finish, delivering finer detail with every print. Additionally, AI-driven quality control systems can detect defects in real-time, ensuring consistent high standards. As these technologies become more accessible, high quality 3D printing services will not only meet the demands of industry but also expand creative possibilities for individual creators and startups alike.

In South Africa and beyond, the convergence of AI and automation is paving the way for a new era of versatile, reliable, and rapid 3D printing. The integration of these innovations promises to unlock previously unreachable levels of complexity and customization, cementing high quality 3D printing services as an indispensable tool for modern manufacturing and design.

Sustainable and Eco-Friendly Printing Solutions

As the horizon of 3D printing continues to expand, emerging trends are propelling high quality 3D printing services into new realms of possibility. Sustainability has become a pivotal focus, with eco-friendly printing solutions gaining momentum. Companies are now harnessing biodegradable resins, recycled filaments, and energy-efficient processes that reduce environmental impact without compromising precision or durability. This shift not only aligns with global sustainability goals but also enhances brand reputation in an increasingly conscientious marketplace.

Innovations in materials and technology are also shaping the future. For instance, the integration of bio-based composites and metal powders is opening doors to more sustainable yet resilient manufacturing options. Meanwhile, advanced software-driven techniques enable the use of renewable resources, fostering a greener approach to high quality 3D printing services. These developments signal a profound evolution—one where eco-consciousness and technological excellence intertwine to redefine what’s possible in additive manufacturing.

Furthermore, the industry is witnessing a surge in design flexibility, driven by novel materials that facilitate complex geometries with minimal waste. This synergy between eco-awareness and innovation ensures that the future of high quality 3D printing services in South Africa and beyond remains vibrant, responsible, and endlessly creative.

Customization and On-Demand Production

Impact on Manufacturing and Design Industries

Emerging trends in high quality 3D printing services are reshaping how industries approach manufacturing and design. Innovations like multi-material printing and faster, more precise techniques enable complex geometries that were once impossible. These advancements are not only increasing efficiency but also expanding creative possibilities for designers and engineers alike.

One notable trend is the integration of AI-driven automation, which streamlines production workflows and enhances accuracy. As a result, manufacturers can deliver faster turnaround times without compromising on detail or durability. This shift is particularly impactful in sectors such as aerospace, healthcare, and automotive, where precision is critical.

Furthermore, sustainable printing solutions are gaining traction. Companies now prioritize eco-friendly materials and energy-efficient processes, aligning with global efforts to reduce the carbon footprint. This focus on sustainability complements the growing demand for high quality 3D printing services that are both innovative and environmentally conscious.

- Increased adoption of composite materials for enhanced strength

- Development of bio-compatible and biodegradable resins

- Expansion of on-demand production to reduce inventory costs

These trends point toward a future where high quality 3D printing services will become even more integral to the manufacturing and design industries, fostering a new era of innovation and sustainability.

0 Comments