Understanding 3D Printing Services

Definition of 3D Printing – Explaining the basics of 3D printing technology

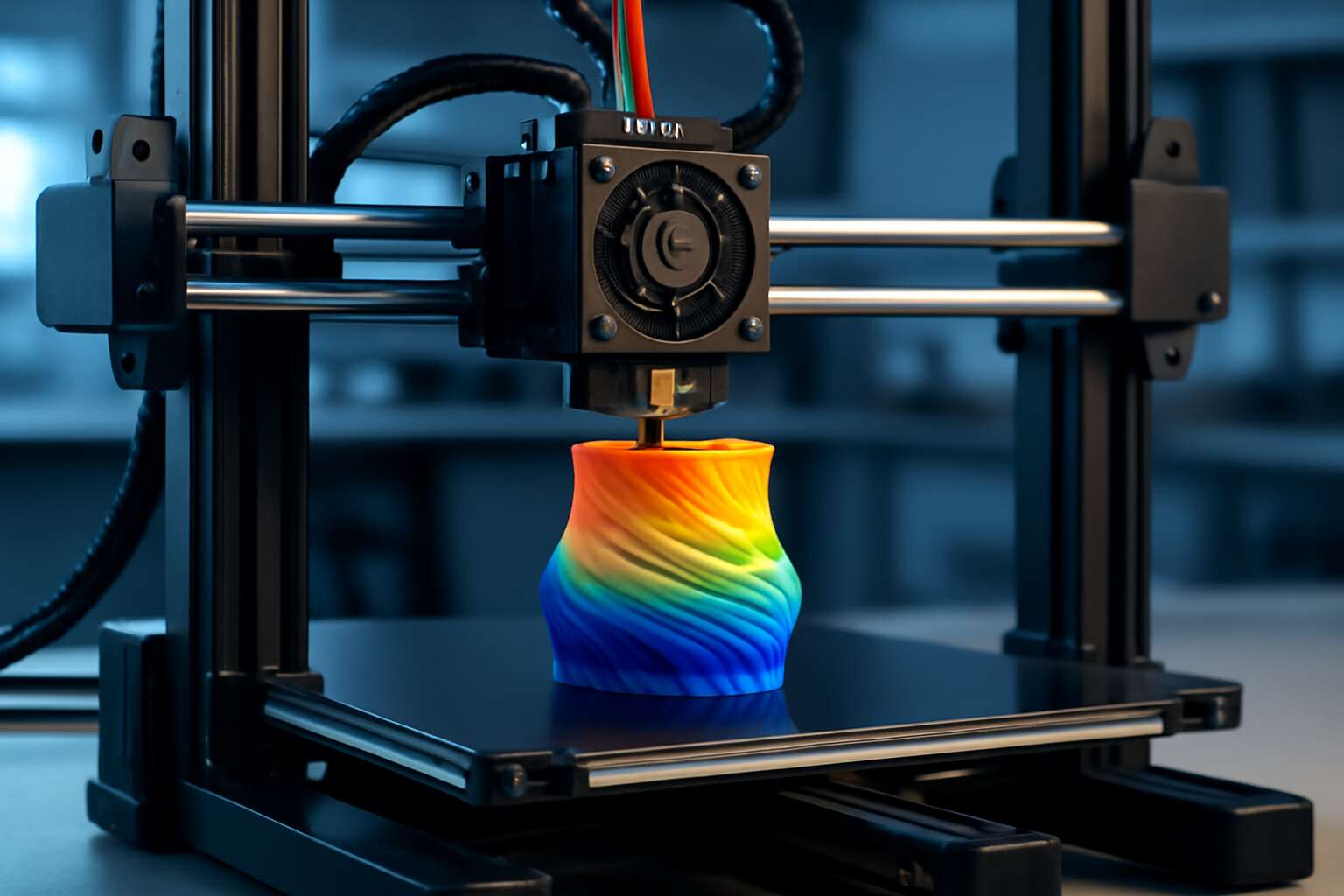

Imagine a world where imagination takes shape with a mere flick of technology’s wand. That is the core of 3D printing — a revolutionary process that transforms digital blueprints into tangible marvels. At its essence, 3D printing is a form of additive manufacturing, layer by layer, building objects with astonishing precision and complexity. It’s no longer confined to sci-fi; today, industries rely heavily on 3D printing services needed to turn concepts into reality, from intricate prototypes to bespoke components.

The magic begins with a digital design, which guides the printer’s nozzle to deposit material precisely where it is needed. Here’s how the process unfolds:

- Creation of a detailed digital model using specialised software.

- Conversion of the model into a format the printer can interpret, often STL or OBJ files.

- Layer-by-layer deposition of materials such as plastics, resins, or metals.

- Cooling or curing processes that solidify each layer, culminating in a finished object.

Understanding the fundamentals of 3D printing is crucial for selecting the right 3d printing services needed to elevate your project from idea to innovation. It’s a craft that blends artistry with engineering, opening doors to endless possibilities.

Types of 3D Printing Technologies – FDM, SLA, SLS, DLP, and other methods

In the shadowed corridors of innovation, the choice of 3D printing technology can shape the destiny of a project. Each method whispers its own secrets, revealing distinct advantages and peculiarities. Fused Deposition Modelling (FDM), for instance, is the most accessible, layering molten thermoplastics with relentless precision. Its dark allure lies in affordability and speed, perfect for prototyping that demands swift execution.

Meanwhile, Stereolithography (SLA) and Digital Light Processing (DLP) harness the power of light to cure liquid resins, casting ethereal objects with astonishing detail and smooth finishes. These are the tools of artisans seeking finesse in every curve and contour. Selective Laser Sintering (SLS), on the other hand, uses a laser to sinter powdered materials, creating complex, durable parts without the need for support structures.

Understanding these 3D printing technologies is crucial when considering the 3d printing services needed to bring visions to life. It’s a dance of shadows and light, where each method offers a different portal into the realm of digital craftsmanship.

Common Industries Using 3D Printing – Automotive, healthcare, aerospace, manufacturing, and prototyping

In the intricate dance of modern manufacturing and innovation, 3D printing services needed span a vast spectrum of industries, each with its own unique demands and expectations. The automotive sector, for example, leverages rapid prototyping and custom parts production—saving time and reducing costs while enhancing design flexibility. Healthcare, on the other hand, demands precision and biocompatibility, where 3D printing transforms patient-specific implants and surgical models from mere concepts into life-changing realities.

Aerospace industries push the boundaries of material strength and lightweight design, often utilising advanced 3d printing services needed to create complex, high-performance components. Meanwhile, manufacturing harnesses additive manufacturing for customised tools and parts, streamlining production lines and reducing waste. The realm of prototyping, perhaps the most immediate beneficiary of diverse 3D printing technologies, benefits from fast turnaround times and the ability to iterate ideas swiftly, often requiring multiple 3d printing services needed for different project phases.

Understanding the specific 3d printing services needed by each industry reveals a profound truth: the choice of technology and service provider is not merely about speed or cost but about the pursuit of excellence in craftsmanship and innovation. Whether it’s a bespoke medical device or a lightweight aerospace component, the right 3D printing service can shape the future—one layer at a time.

Key 3D Printing Services Businesses Need

Rapid Prototyping Services – Transforming product development with quick turnarounds

In the fast-paced world of product development, staying ahead means embracing rapid prototyping services that deliver precision and speed. The 3D printing services needed by key businesses aren’t just about creating models—they’re about transforming ideas into tangible prototypes in record time. This agility allows designers and engineers to refine their concepts swiftly, reducing time-to-market and cutting costs significantly.

Imagine the impact of turning a complex design into a physical prototype within days, not weeks. Rapid prototyping not only accelerates the innovation cycle but also fosters a culture of experimentation and iteration. When businesses leverage advanced 3D printing services, they gain a competitive edge by making smarter, faster decisions—crucial in industries such as aerospace, healthcare, and automotive manufacturing.

To meet these needs effectively, many companies are now prioritising:

- High-resolution printing for detailed prototypes

- Material versatility to simulate real-world conditions

- Flexible turnaround times for iterative testing

By integrating these elements into their 3D printing services needed, businesses can push boundaries and achieve breakthroughs that once seemed unattainable. Rapid prototyping is no longer just an option; it’s an essential component of modern product development.

Customized Manufacturing Solutions – Personalized products and small-batch production

In a world where individuality reigns supreme, the demand for customized manufacturing solutions has surged like an unstoppable tide. Businesses seeking to carve out unique identities crave more than mass-produced sameness; they yearn for products that mirror their distinct vision. The 3d printing services needed by these innovators offer precisely that—personalised products crafted with meticulous precision. This technology transforms sterile concepts into tactile masterpieces, allowing for small-batch production that embraces the elegance of bespoke craftsmanship.

Whether it’s a one-of-a-kind jewellery piece, tailored medical devices, or specialised automotive components, the power of 3D printing ignites the spark of innovation. This approach not only reduces waste and shortens lead times but also invites a new era of creative freedom. Businesses can now experiment with intricate designs, select from a vast array of materials, and produce in limited runs without the hefty overheads traditionally associated with custom manufacturing.

Indeed, the 3d printing services needed in today’s market are characterised by versatility and adaptability. From rapid prototyping to short-run production, these solutions enable companies to respond swiftly to market trends and customer desires. The ability to turn an idea into a tangible product—quickly and accurately—catapults enterprises into a realm where differentiation is king and innovation is the currency of success.

Replacement Parts Production – On-demand manufacturing for obsolete or hard-to-find components

In a world where machinery and technology often seem to disappear into the background, the reality of on-demand manufacturing becomes a beacon of hope—especially when it comes to replacement parts. The 3d printing services needed for producing obsolete or hard-to-find components are revolutionising maintenance and repair processes across industries. Imagine the frustration of searching high and low for an elusive part, only to discover it’s no longer in production. Now, with advanced 3D printing technology, that frustration can be swiftly alleviated.

These services empower businesses to create customised replacement parts rapidly, reducing downtime and extending the lifespan of essential equipment. Whether it’s a vintage machine or specialised automotive component, additive manufacturing offers a bespoke solution. The ability to produce complex geometries and specialised materials on demand makes 3D printing an invaluable tool for maintaining operational continuity. As industries embrace this innovative approach, the 3d printing services needed are becoming more versatile and accessible than ever before.

- Producing customised, hard-to-find parts swiftly and accurately

- Reducing inventory costs by manufacturing components only when needed

- Extending machinery life through precise replication of obsolete components

By leveraging these services, companies can navigate the challenges of sourcing rare parts with confidence. The magic of on-demand 3d printing not only saves time but also offers a sustainable alternative to traditional manufacturing—eliminating excess stock and waste. As the demand for seamless, fast, and reliable replacement part production grows, so too does the importance of 3d printing services needed in today’s competitive landscape.

Factors to Consider When Choosing 3D Printing Services

Material Compatibility – Types of materials supported and their applications

Choosing the right 3D printing services needed hinges largely on material compatibility—an aspect often overlooked in favour of technological prowess but just as vital. Not all 3D printing materials support the same applications, and a mismatch can lead to costly setbacks or inferior products. For instance, if you require a durable component for industrial use, materials like nylon or metal powders are indispensable. Conversely, for prototypes or visual models, resin-based options might suffice, offering finer detail but less strength.

Understanding the spectrum of supported materials can be a game-changer in your decision-making. Typically, a comprehensive 3D printing service provider will support a range of materials, including:

- ABS and PLA plastics for functional prototypes

- Resins for high-resolution, detailed models

- Metal composites for high-strength applications

- Flexible filaments for elastomeric parts

Matching your project’s specific needs with the appropriate material ensures optimal performance and cost-efficiency—an essential consideration when evaluating the 3D printing services needed for your venture’s success.

Print Quality and Resolution – Ensuring precision and surface finish

When selecting 3D printing services needed for your project, print quality and resolution are often the deciding factors. Precision and surface finish can make or break the final product, particularly when detailed aesthetics or tight tolerances are required. A high-resolution 3D print captures intricate features, giving your prototypes or models a professional edge that’s essential in competitive markets. Conversely, lower resolution might suffice for rougher, functional parts where detail isn’t paramount.

Quality consistency across batches is equally important. Reliable 3D printing services needed should demonstrate a commitment to precision, ensuring each print meets your specifications. Whether you’re producing visual models or functional prototypes, understanding the capabilities of their technology—like layer resolution and surface smoothness—can significantly influence your project’s success. Remember, investing in superior print resolution often results in reduced post-processing, saving both time and costs in the long run.

Turnaround Time and Cost – Balancing speed and budget constraints

Speed and budget are often at odds in 3D printing projects. Finding the right balance between turnaround time and cost can make or break your product timeline. Quick delivery is crucial for rapid prototyping and iterative design, but it usually comes at a premium. Conversely, more economical options may take longer, impacting your project schedule. It’s essential to clearly define your priorities when choosing 3D printing services needed for your project.

Many providers offer tiered options, allowing you to select between fast and affordable solutions. For time-sensitive projects, look for services that guarantee quick turnaround times without sacrificing quality. If cost is a bigger concern, explore bulk discounts or lower-resolution options that still meet your functional requirements. A transparent communication process with your chosen provider helps ensure expectations are aligned, avoiding surprises along the way. Ultimately, understanding the interplay between turnaround time and cost allows you to select 3D printing services needed that fit your specific needs perfectly.

Technology Capabilities – Availability of advanced or industry-specific 3D printing methods

When selecting 3D printing services needed for your project, the spectrum of technology capabilities can feel like exploring a vast, enchanted forest. Advanced or industry-specific 3D printing methods—such as multi-material printing, high-resolution SLA, or specialised SLS—offer bespoke solutions that can transform your ideas into tangible marvels. The availability of these cutting-edge techniques often distinguishes a good provider from a truly exceptional one.

It’s vital to assess whether the provider’s technological repertoire aligns with your project’s unique demands. For instance, if you require intricate detailing or durable prototypes, ensure they offer high-precision print quality and material compatibility. Many providers also boast tiered options, allowing you to navigate between rapid prototyping and meticulous, detail-rich production.

Ultimately, the right choice of 3D printing services needed hinges on their capacity to marry advanced technology with your specific vision—turning your aspirations into reality with both finesse and efficiency.

Experience and Certifications – Assessing provider expertise and quality assurance

Choosing the right 3D printing services needed for your project is more than a simple transaction; it’s a meticulous dance of trust, expertise, and vision. Experience and certifications serve as the silent guarantees of quality, echoing a provider’s commitment to excellence. When assessing potential partners, look beyond surface-level credentials—delve into their track record of delivering complex, industry-specific solutions that demand finesse and precision.

Certifications such as ISO 9001 or ASTM compliance often stand as testaments to rigorous quality assurance processes. An experienced provider will possess a portfolio that showcases diverse projects, demonstrating their adeptness across different industries and applications. Remember, in the realm of 3D printing services needed, the difference between a good and a great provider can be measured by their ability to consistently marry advanced technology with your unique requirements.

To truly gauge expertise, consider asking about their team’s background and ongoing training—because in this rapidly evolving field, staying ahead of technological advancements is paramount. Ultimately, the most compelling choice is one that embodies both seasoned mastery and a passion for innovation, ensuring your ideas are realised with unparalleled precision and reliability.

Benefits of Using Professional 3D Printing Services

Enhanced Product Development – Accelerating design iterations

In the realm of product innovation, speed and precision are paramount. Professional 3D printing services needed by forward-thinking companies can dramatically accelerate the journey from concept to tangible prototype. By leveraging advanced technology, these services enable rapid design iterations, allowing creators to refine their ideas with remarkable agility. This not only shortens development cycles but also reduces costs—key factors in maintaining a competitive edge in today’s fast-paced markets.

Enhanced product development through expert 3D printing services opens the door to unparalleled flexibility. Whether it’s fine-tuning complex geometries or testing functional prototypes, the ability to iterate swiftly ensures that ideas evolve into market-ready solutions with finesse. Furthermore, the integration of high-resolution printing and material compatibility offers a level of detail and durability that supports innovative experimentation. Embracing these services is no longer a luxury but a strategic necessity for those eager to transform visions into reality efficiently and effectively.

Cost-Effective Production – Reducing waste and tooling costs

Cost-efficient production is a game-changer in modern manufacturing. Professional 3D printing services needed by companies aiming to optimise budgets can significantly reduce waste and tooling expenses. Unlike traditional methods, additive manufacturing produces parts layer by layer, meaning there’s minimal material wastage. This precision not only cuts costs but also streamlines the entire production process.

Furthermore, 3D printing services needed often eliminate the need for costly tooling setups. For small batches or customised items, the expenses associated with moulds and fixtures are non-existent. As a result, companies can bring prototypes or limited runs to market faster and more affordably.

Some providers even offer flexible material options—supporting various plastics, resins, and metals—allowing for optimised performance without overspending. This strategic advantage makes 3D printing services needed an invaluable asset for businesses seeking to compete efficiently in tight-margin markets.

Design Flexibility – Creating complex geometries and customized prototypes

In the realm of modern manufacturing, the allure of design flexibility offered by professional 3D printing services needed by innovative companies is nothing short of revolutionary. Unlike traditional methods that often confine creators within the bounds of moulds and tooling constraints, additive manufacturing opens a portal to uncharted geometries and customised prototypes that would be impossible with conventional techniques.

Imagine crafting intricate lattice structures or organic shapes that seamlessly blend aesthetics with functionality—this is the magic that 3D printing services needed can deliver. These capabilities empower designers to push boundaries, transforming ideas into tangible realities with astonishing precision. The freedom to iterate rapidly and refine complex geometries means that creative visions are no longer limited by manufacturing constraints, but rather, liberated by technological prowess.

In essence, the true benefit of using professional 3D printing services lies in their ability to turn inventive concepts into reality—fast, precise, and cost-efficient. Whether it’s for bespoke prototypes or small batch production, these services are an indispensable tool in the arsenal of any forward-thinking enterprise seeking to innovate without compromise.

Quality and Reliability – Consistent and high-quality outputs

In a landscape where precision and consistency are paramount, the true strength of professional 3D printing services needed by innovative enterprises lies in their unwavering quality and reliability. When every layer of a prototype must meet exacting standards, the assurance of high-calibre output becomes a cornerstone of their success. Skilled providers employ rigorous quality assurance protocols, harnessing advanced calibration techniques to ensure each print maintains impeccable fidelity.

This dedication to excellence manifests in surfaces that are not only visually stunning but also functionally sound, meeting industry-specific tolerances with steadfast consistency. For those seeking to transform ideas into tangible marvels, the confidence that their 3D printed components will perform reliably is invaluable. Whether for complex prototypes or delicate miniature models, the hallmark of reputable 3D printing services needed is a reputation for delivering dependable, top-tier results every time.

Future Trends in 3D Printing Services

Innovations in Material Science – New functional and composite materials

As technology advances, the horizon of 3D printing services needed shifts towards unprecedented innovation in material science. The future is not merely about creating objects but redefining what materials can do—combining strength, flexibility, and even functionality in ways previously thought impossible. New composite materials are emerging, blending polymers with carbon fibre or metal powders to produce durable, lightweight components that challenge traditional manufacturing constraints.

This evolution is driven by an insatiable quest for efficiency and sustainability. Imagine materials that can self-heal or adapt to environmental changes—these are no longer the realm of science fiction. As the industry explores these frontiers, the integration of functional materials capable of conducting electricity or responding to stimuli will transform sectors like aerospace, healthcare, and automotive manufacturing. The 3d printing services needed will increasingly demand expertise in handling these complex materials, ensuring precision and reliability at every layer of production.

In essence, the future of 3D printing hinges on material science breakthroughs—pushing boundaries and unlocking new potentials for customisation, durability, and performance. It’s an exciting era where the only limit is our imagination, and the right 3D printing service provider will be essential to turn visionary ideas into tangible realities.

Integration with CAD and AI – Streamlining design to production workflows

In the ever-evolving tapestry of technological innovation, the future of 3D printing services needed is being reshaped by the seamless integration of CAD and AI. Imagine a world where design ideas are no longer confined by manual constraints but are transformed into digital symphonies, orchestrated by intelligent algorithms. This synergy not only accelerates the journey from concept to reality but elevates it to an art form—where precision and creativity dance in harmony.

Streamlining workflows through advanced software integration ensures that each layer of the 3D printed masterpiece embodies meticulous accuracy. As AI-driven optimisation refines geometries and reduces material waste, the entire process becomes a ballet of efficiency. The days of lengthy prototyping cycles are giving way to rapid, adaptive manufacturing cycles, making the 3D printing services needed more responsive and cost-effective than ever before.

- Enhanced digital collaboration tools foster real-time adjustments, allowing designers and engineers to innovate without delay.

- Automated error detection and correction elevate the reliability of final products, meeting the high standards demanded by industries like aerospace and healthcare.

- Integration with cloud-based platforms ensures that cutting-edge 3D printing services needed are accessible globally, breaking geographical barriers and democratizing innovation.

Therefore, the evolution of 3D printing services needed hinges on harnessing the power of CAD and AI—transforming intricate design visions into tangible, high-quality realities with unprecedented speed and precision. In this new dawn, the only limit is the scope of our imagination, and the right technological blend will unlock the boundless potential awaiting within each layer of print.

Sustainability Initiatives – Eco-friendly materials and processes

As the world’s obsession with sustainability intensifies, 3D printing services needed are increasingly leaning towards eco-friendly initiatives. Imagine a future where every layer of your prototype is built with materials that don’t just serve their purpose but also save the planet—sounds like a utopian dream, right? Well, it’s rapidly becoming reality. Material scientists are pioneering bio-based filaments, recycled plastics, and even biodegradable resins that break down harmlessly after fulfilling their purpose. These innovations not only reduce the carbon footprint but also appeal to environmentally conscious clients who demand green credentials.

On top of greener materials, the processes behind 3D printing are evolving. Techniques such as solar-powered printers and water-based binding agents are making the entire manufacturing ecosystem more sustainable. This shift isn’t just about doing good; it’s about aligning with the future market demands where eco-friendliness is a key differentiator. The 3d printing services needed are now more than ever about marrying innovation with responsibility, ensuring that progress doesn’t come at the planet’s expense. Sustainability initiatives in 3D printing are transforming the industry into a beacon of environmental stewardship, one layer at a time.

Scaling for Mass Production – From prototyping to small-scale manufacturing

As industries evolve, the promise of 3D printing scaling for mass production is transforming the manufacturing landscape. Once confined to rapid prototyping, 3D printing is now opening doors to small-scale manufacturing on a much larger scale. This shift is driven by advancements in printer speed, material versatility, and process reliability, making 3D printing services needed more than ever to meet increasing demand. Companies are recognising that additive manufacturing can be a cost-effective, flexible alternative to traditional methods, especially for customised, low-volume production runs.

Future trends indicate that 3D printing will support complex geometries and personalised products at an industrial scale. Innovations such as multi-material printers and hybrid manufacturing systems are paving the way for production lines where parts are built layer-by-layer with precision, reducing waste and lead times. To stay competitive, enterprises will rely heavily on 3D printing services needed to scale their operations efficiently, offering quick turnarounds while maintaining quality. The industry’s evolution points towards a seamless integration of 3D printing into mainstream manufacturing, where versatility and speed are paramount.

0 Comments